Made to last

When it comes to manufacturing, our products have as much northern grit as we do

We could begin by saying that we design and build our furniture to meet UK, European and American standards, and that we are accredited to ISO 9001:2015, but wouldn’t you expect that? We have one test that far exceeds them all, and that is, does it meet our standards?

We confidence test our furniture to 25% above the UK standard – and only when we’re happy, do we send it out for external independent testing. To us, ‘over engineered’ is a compliment, because our products are made to not simply pass a quality test, but to stand the test of time.

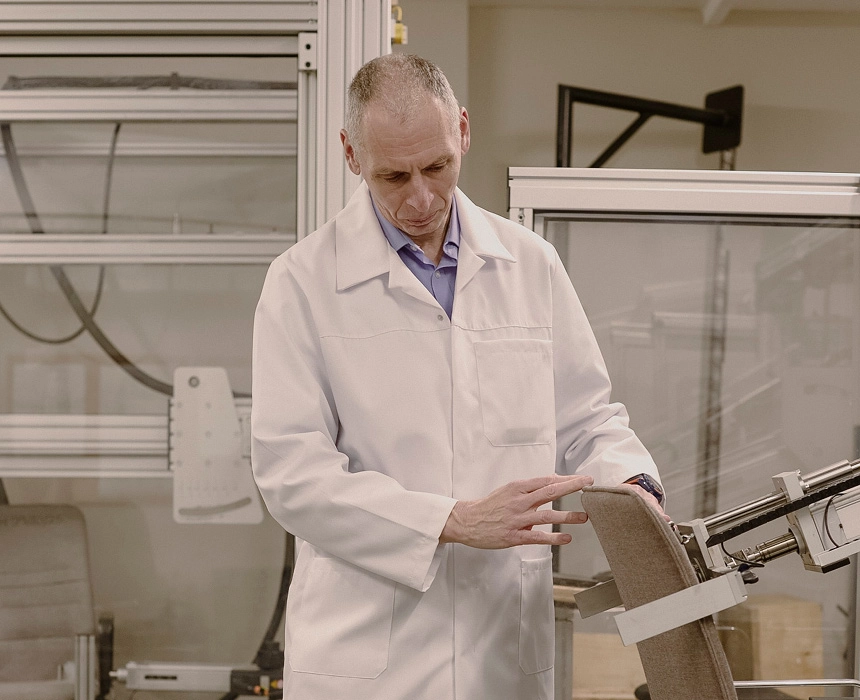

Our experienced engineers are involved from the very start

Watch our Senior Design Engineer Ian McKnight explain the compromise that takes place between Engineers and Designers at The Senator Group.

VIEW VIDEOWe test our chairs with brute force to see what they're made of

When we design a new product, we make around ten prototypes, perfecting the style, comfort, strength, stability and durability, until we’re 100% happy.

Our Hanke Pruftechnik test rig tries its best to break our chairs. It puts the back and seat through 200,000 cycles and 330 newtons of pressure, which is the equivalent of 5 years hard use. If we even suspect a weakness, we turn up the pressure some more.

We test a chair’s arm 60,000 times, applying 40kg of weight to just one arm, to test durability. Excessive force is applied to test the strength of each arm, where we place a 112Kg weight to see if we can make it fracture.

We quality test our chairs with brute force – hitting them ten times with a weighted pendulum, (much like a sledgehammer), on the seat, back and arms to see what they’re made of. We apply a 100kg load to the back, to see if we can split the frame.

When it comes to office chairs, we test the durability of the arm pads, by ramming it under a desk over and over again. Is it a required test? No. But we know that’s what happens in the real world.

We’ve commissioned our own testing rig, where we put desking and tables through the most severe ‘destruction’ testing

We have commissioned our own testing rig, where we put desking and tables through the most severe ‘destruction’ testing. And because we design desks and tables in all shapes and sizes, no test is exactly the same.

To test strength, we apply 130kg of pressure, both horizontally and vertically to a desk or tabletop. We drop a 25kg free falling weight on to a product’s edge, to see how it performs under impact, and we drop it – again ten times; before doing a ‘tip test’, pushing and pulling even the tallest of lockers, to try and knock them off balance.

We put our tables through 20,000 cycles of horizontal and vertical durability testing, and our desking through 10,000 cycles, adding force in four different directions within each cycle. Even if a solitary bolt shakes loose, that’s a failure.

Over the years, we’ve even made our own robots to test our products, from repeatedly testing switches, to simulating the actions required of our height adjustable desking over its lifetime. We also work with colleges and universities, inviting bright young minds to invent new robots to use in our quality testing.

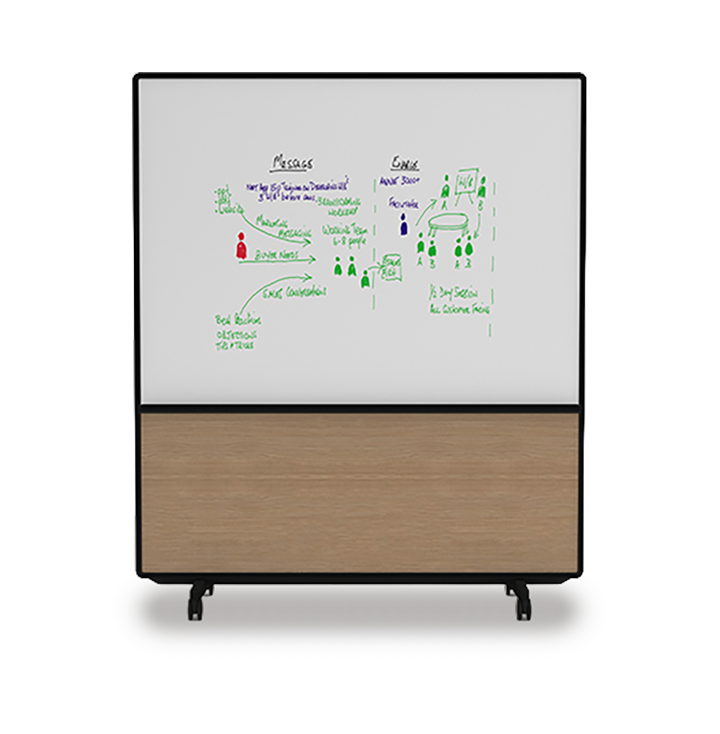

Product spotlight: Adapt Wall

When testing our Adapt Wall prototype, we applied over half of tonne of weight to see if the castors would hold up; and for 2000 cycles; they were run over a 2mm lip, simulating a typical room divider. Did we manage to break them? Of course, we did, which is why the storage model has castors that can carry more than the average elephant.

DISCOVER MOREWe test quality at every stage, before completing a final fourteen-point inspection

How many stitches are in a Cardita stool? 4612. How do we know? Because we quality check each and every one.

Our furniture passes through thousands of quality checks as each component passes through the numerous processes in our factories. Some checks are automated – such as special machinery to check that our panel drill holes are in alignment, and some rely on the years of experience held by our expert quality inspectors.

Take Mike in our seating factory who has worked for us for almost forty years. He has a 14 point final checklist for our soft seating and every piece goes through a complete visual and physical inspection before approval. From seam alignment to stitch integrity, he ensures not a wrinkle or crease gets past his eagle eye.